At Reeman Robotics, we are committed to revolutionizing industrial automation with cutting-edge technology. Our latest innovation, the Giraffe Factory Delivery Robot, embodies this commitment, offering unparalleled efficiency, adaptability, and intelligence. Designed to excel in the most demanding factory environments, Giraffe sets a new standard for autonomous delivery solutions.

Advanced Perception Technology

Giraffe utilizes a sophisticated combination of lidar and three sets of 3D camera fusion technology to achieve comprehensive environmental perception. This advanced sensing capability allows Giraffe to navigate complex factory settings with precision and reliability. The adjustable lidar height, ranging from 1.62 to 1.8 meters, ensures that Giraffe maintains accurate navigation even in environments with frequent movement of objects and obstacles. This adaptability significantly enhances its mapping and positioning accuracy, making it ideal for factories with dynamic layouts.

Robust Load Capacity

Engineered for heavy-duty performance, Giraffe boasts a substantial load capacity of up to 100 kg. Its chassis, constructed from durable sheet metal, ensures stability and prevents deformation under load. Whether transporting heavy boxes or other industrial materials, Giraffe delivers consistent, reliable performance.

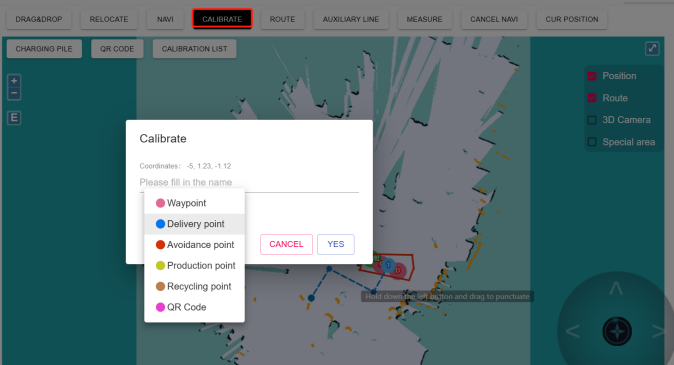

Autonomous Navigation with SLAM 2.0

At the heart of Giraffe's autonomy is Reeman's proprietary SLAM 2.0 system. This state-of-the-art autonomous positioning and navigation system provides high-precision navigation without the need for coding. SLAM 2.0 allows Giraffe to dynamically adjust its path, avoiding obstacles and optimizing delivery routes in real-time. The system supports central dispatching and multi-machine collaboration, ensuring seamless and orderly operation even in large-scale industrial environments.

Open SDK Platform and Customization

To meet the diverse needs of our clients, Giraffe comes with an open SDK platform, offering a rich array of API interfaces. This flexibility supports secondary development and customized services, enabling integration with existing systems and bespoke functionality. Comprehensive technical support documentation and remote navigation capabilities simplify the deployment process, while real-time chassis status monitoring enhances operational efficiency.

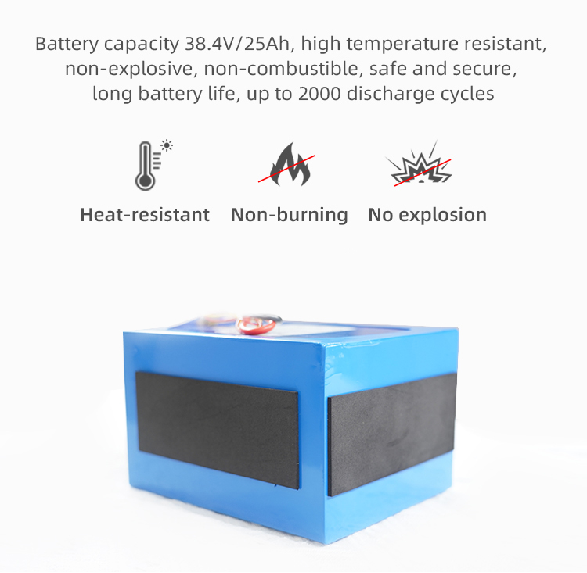

Safety and Reliability

Safety is paramount in industrial automation, and Giraffe is equipped with a range of features to ensure secure operation. Its 270° autonomous obstacle avoidance system and flexible steering allow for safe navigation through busy factory floors. Powered by a 38.4V/25Ah lithium iron phosphate battery, Giraffe is both safe and environmentally friendly, with non-combustible and non-explosive properties. Additionally, Giraffe automatically returns to its charging station when battery levels are low, eliminating the need for manual intervention and ensuring continuous operation.

Optimized for Complex Environments

Giraffe excels in environments where frequent and complex deliveries are required. The adjustable lidar height and advanced perception technologies enable it to maintain accurate positioning and mapping even in cluttered and changing environments. This feature is particularly beneficial in factories where objects are frequently moved, ensuring that Giraffe can navigate and perform its tasks with exceptional precision.

Conclusion

Giraffe represents the future of factory automation, combining robust hardware with sophisticated software to deliver unmatched performance and adaptability. Its advanced perception technology, high load capacity, autonomous navigation, and customizable platform make it an indispensable asset for modern factories. By integrating Giraffe into your operations, you can enhance efficiency, reduce manual labor, and stay ahead in the competitive industrial landscape. Discover the potential of Giraffe and transform your factory's delivery operations today with Reeman Robotics.

Please click on the link below to read more:

Revolutionizing Material Handling: The Ironhide Autonomous Forklift By Reeman Robotics

Control And Navigation Of AGVs And AMRs

What Is An Autonomous Forklift?

Would you like to know more about robots:https://www.reemanrobot.com/

robot mop,mopping robot,vacuum cleaner robot,clean robot,commercial cleaning robot,floor cleaning,sweeper robot,robots cleaning,vacuum robot,cleaning robot,wet and dry robot vacuum cleaner,commercial mopping robot,sweeping robot ,uv-c robot vacuum cleaner,floor cleaning robot,robot cleaner,floor mopping machine,robot mop cleaner,vacuum cleaner,robot vacuum mop,vacuum cleaning robot,mop robot,robot cleaner vacuum,cleaner mop robot,uvc robot cleaning,cleaning robots smart vacuum,cleaning robot commercial,intelligent cleaning robot,commercial mop robot