Traditional Forklifts vs. AMR Forklifts:

Traditional forklifts have long been the workhorses of warehouses and distribution centers, relying on operators to navigate and execute precise material movements. In contrast, AMR forklifts represent a leap forward in automation, eliminating the need for human drivers and embracing a fully autonomous approach. The key distinctions lie in their navigation systems, adaptability, and operational efficiency.

VS

VS

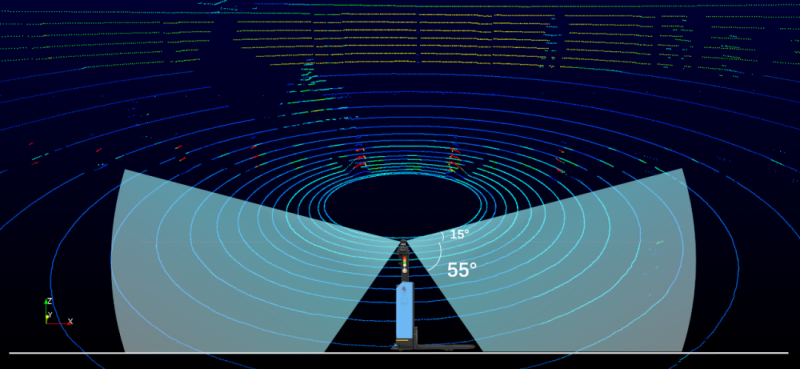

Navigation Technology:

One of the fundamental differences between traditional forklifts and AMR forklifts is the way they navigate their environments. Traditional forklifts require skilled human operators to navigate through designated pathways, often marked by racks or floor indicators. On the other hand, AMR forklifts leverage advanced technologies such as LiDAR (Light Detection and Ranging), cameras, and sensors to autonomously navigate and map their surroundings. This allows them to adapt seamlessly to changing layouts and unforeseen obstacles, enhancing overall operational flexibility.

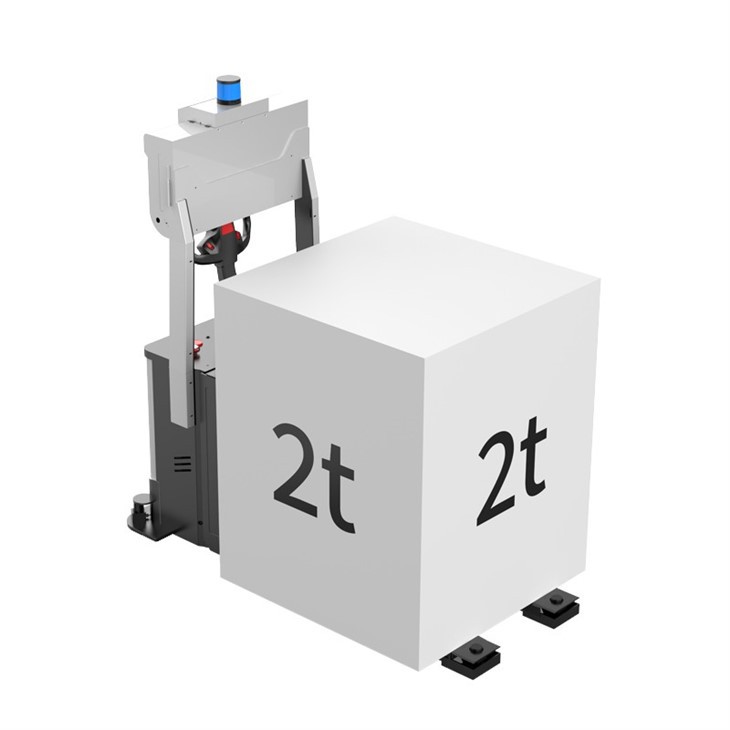

Adaptability:

AMR forklifts excel in adaptability, effortlessly integrating with existing warehouse infrastructure and adjusting to evolving operational needs. Unlike traditional forklifts, which may require dedicated lanes or fixed pathways, AMR forklifts can dynamically plan routes, optimize traffic flow, and efficiently respond to real-time changes in the environment. This adaptability significantly reduces the need for costly infrastructure modifications and enhances the overall scalability of material handling operations.

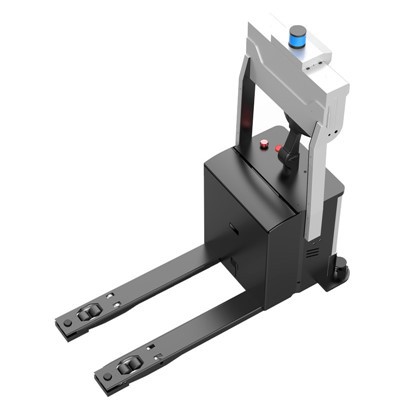

Driveless Technology in AMR Forklifts:

The core innovation that propels AMR forklifts into the future is their driveless technology. These robotic vehicles leverage a combination of sophisticated sensors, machine learning algorithms, and real-time data processing to navigate and perform tasks without human intervention. The central processing unit interprets environmental data, enabling the AMR forklift to make instantaneous decisions about navigation, load handling, and safety protocols. This driveless capability not only boosts operational efficiency but also ensures a safer working environment by eliminating the risk of human-related errors.

Benefits of AMR Forklifts:

The adoption of AMR forklifts brings about a myriad of benefits for businesses engaged in material handling operations. Some key advantages include:

Increased Efficiency: AMR forklifts operate 24/7 without the need for breaks or shift changes, ensuring continuous productivity and reducing idle time.

Enhanced Safety: The elimination of human operators minimizes the risk of accidents and injuries, creating a safer working environment for all stakeholders.

Flexibility and Scalability: AMR forklifts can easily adapt to changing warehouse layouts and accommodate fluctuations in demand, providing a scalable solution for dynamic business needs.

Cost Savings: With reduced reliance on human labor and increased operational efficiency, businesses can realize significant cost savings over time, making AMR forklifts a financially prudent investment.

The Future of AMR Forklifts:

As technology continues to advance, the future of AMR forklifts holds exciting possibilities. Predictive maintenance algorithms, further integration with the Internet of Things (IoT), and continuous improvements in artificial intelligence will enhance the capabilities of AMR forklifts. Moreover, increased collaboration and communication between multiple AMR forklifts within a facility will enable seamless coordination, optimizing material flow and warehouse operations.

Conclusion:

The evolution from traditional forklifts to AMR forklifts marks a transformative chapter in the realm of material handling. With their driveless technology, adaptability, and a host of operational benefits, AMR forklifts are poised to redefine efficiency and safety standards in warehouses and distribution centers. As businesses embrace these autonomous solutions, the future promises an era of heightened productivity, cost savings, and continuous innovation in the field of material handling automation.

Please click on the link below to read more:

Control And Navigation Of AGVs And AMRs

What Is An Autonomous Forklift?

What Is An Autonomous Forklift?

Would you like to know more about robots:https://www.reemanrobot.com/