With the continuous development of human society, robot technology is also advancing rapidly, and robots have made significant improvements in functionality and performance. So, how are robots created? Now, we will take Reeman Robot Company's "Moon Knight 3.0" product as an example to understand some of the main components of robot manufacturing through 3D demonstration.

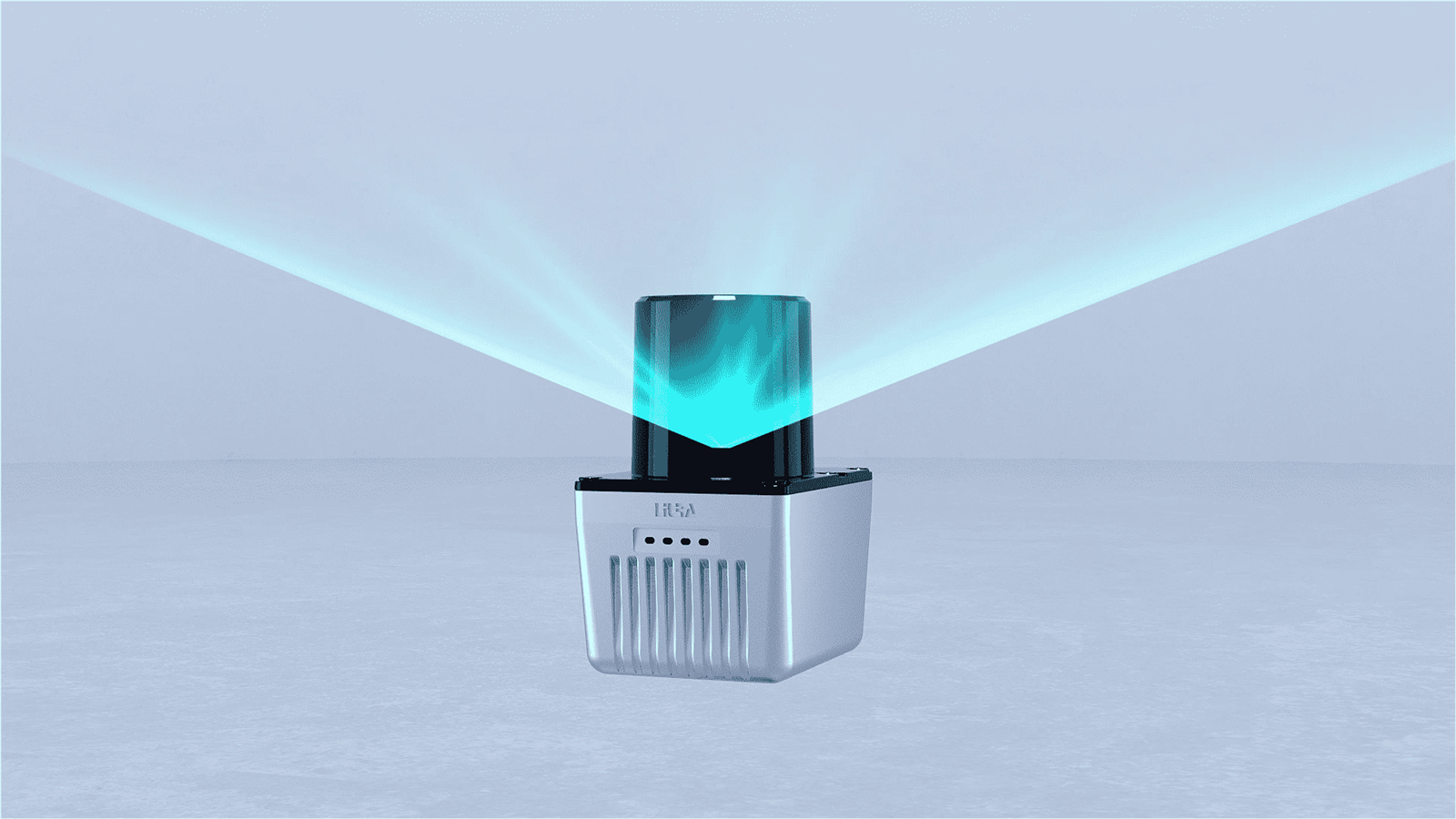

The first is lidar, which is used to create maps and scan the environment for localization by measuring the reflection time between a laser beam and an object. This enables the robot to generate high-precision three-dimensional maps and achieve precise navigation in complex environments.

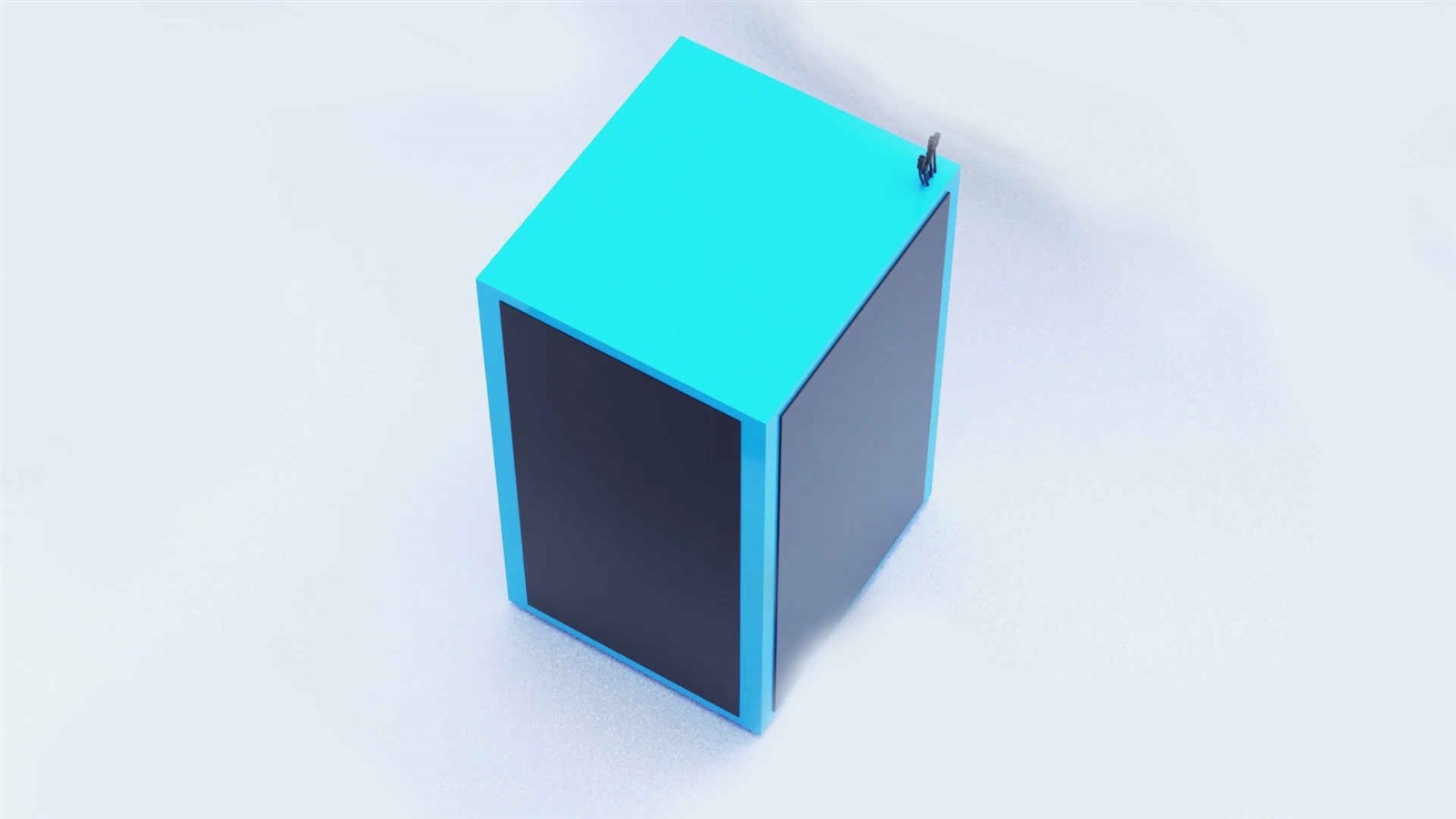

Lithium iron phosphate batteries are widely used due to their high safety, stability, long life and other advantages. These features ensure that the robot has a reliable power supply, allowing it to operate for long periods of time.https://www.reemanrobot.com/

The 3D camera can capture depth information and provide the robot with three-dimensional obstacle avoidance capabilities. Not only can it identify and avoid obstacles ahead, it can also detect differences in the ground to prevent the robot from falling or colliding.

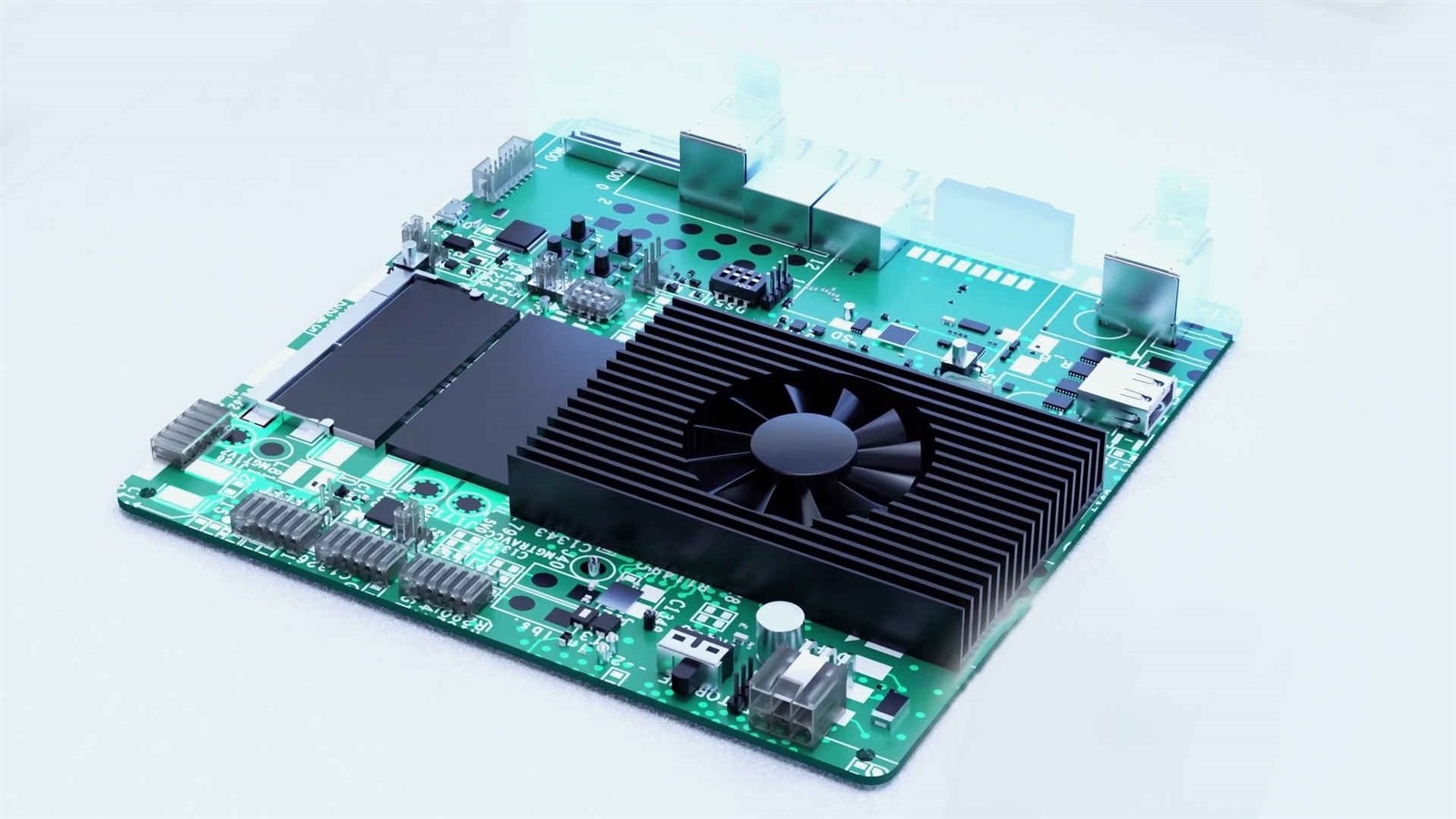

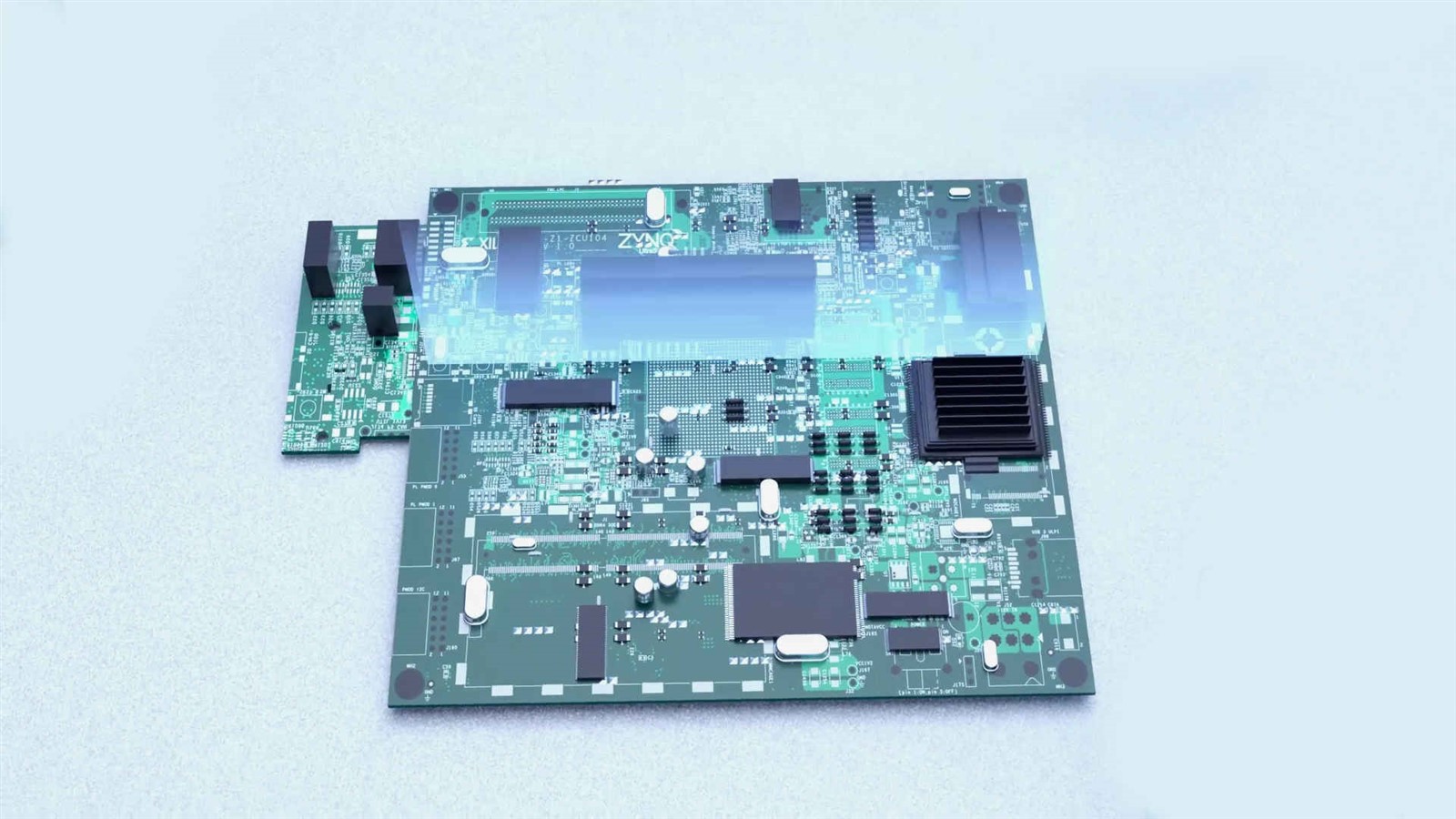

The navigation mainboard undertakes the calculation tasks of the navigation algorithm and provides the navigation path required when the robot is running. In addition, it also works with other peripherals to implement functions such as obstacle avoidance, fall prevention, scheduling, and one-click calling, and provides hardware support for the web side.

Android motherboards are mainly used for the development and testing of Android applications. It is responsible for screen display and operation, and provides hardware support for application development.

The function of the power strip is to provide a stable power supply and convert the power supply's electrical energy into various voltage and current levels to meet the power needs of the robot's computer hardware and other equipment.

An in-wheel motor is an electric drive system that integrates an electric motor directly into the wheel and a built-in encoder to measure the wheel's rotation. This allows the robot to accurately measure its distance traveled and angle of rotation, allowing for precise navigation.

The main function of the drive box is to provide power, signal and protection to ensure accurate movement and control of electric equipment or actuators as required.

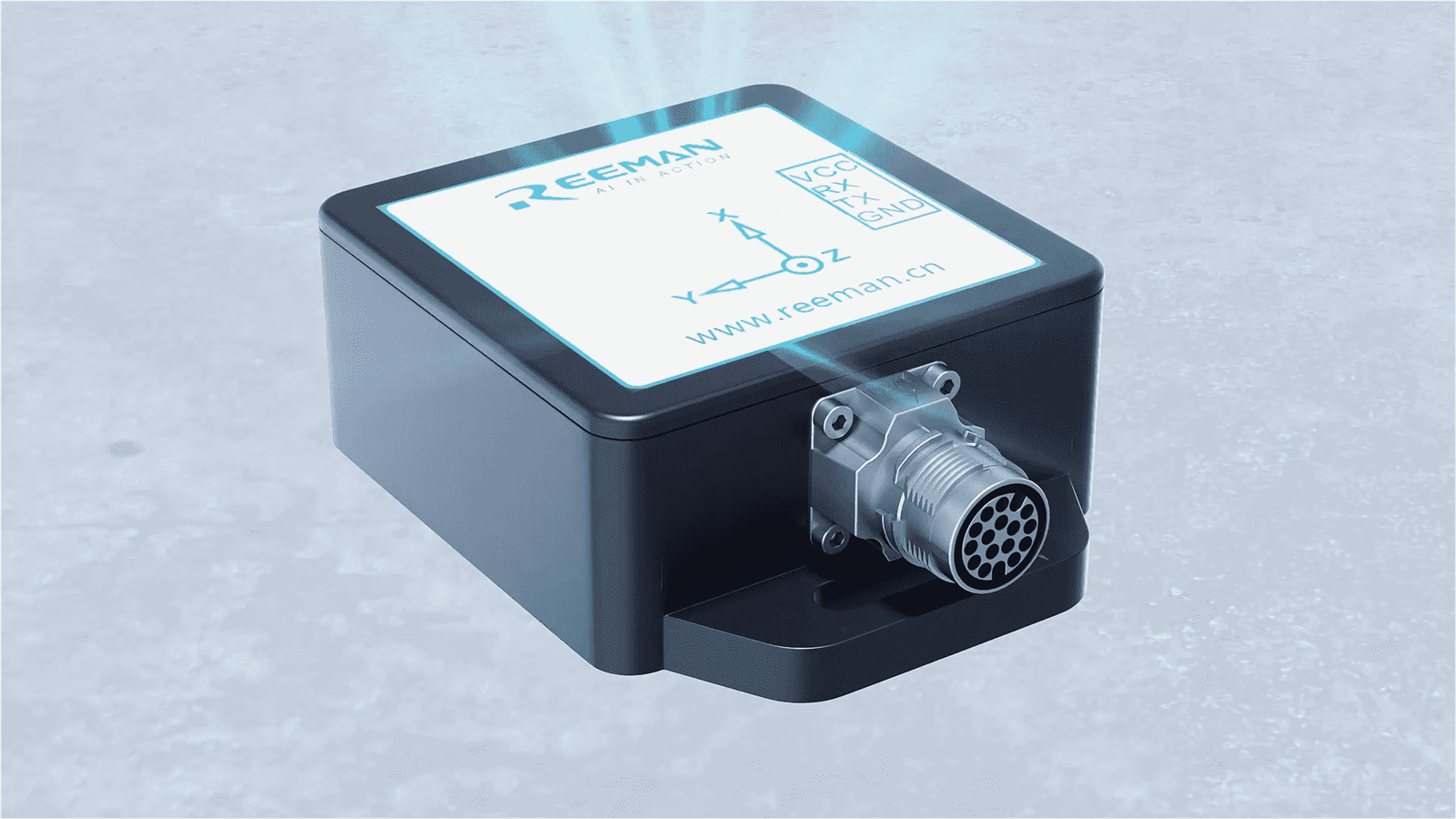

A gyroscope is a device used to measure or maintain direction. It can detect changes in the angular velocity of a robot, thereby helping the robot understand its current attitude or direction and ensure stable movement.

The suspension system helps the robot adapt to uneven ground, reduces vibration, and maintains the robot's stability. This system can include springs, shock absorbers or other shock-absorbing devices to absorb shock caused by uneven ground and ensure that the robot chassis remains level.

Universal wheels help achieve multi-directional movement, allowing robots and automation equipment to move flexibly in various environments while maintaining product balance.

Through the combination and collaborative work of these key components, the robot can achieve high-precision positioning, navigation, obstacle avoidance and stable movement, thus becoming a powerful assistant in various application fields. Continuous advances and innovations in robotics will continue to propel our society to greater heights.

Please click on the link below to read more:

How can a robot move

Robots: The Bridge Connecting AI with the Physical World

Would you like to know more about robots:https://deliveryrobotic.com/

robotics、reeman 、ai、delivery robot、autonomous delivery robot 、factory、handling、handling robot、agv robot、robot chassis、mobile robot、autonomous mobile robot、mobile robot chassis、agv、AMR 、AMR robot、logistics robot、handling robot、agv chassis、package delivery robot、factory delivery robots, workshop material delivery robots、transport robot、porter robot、grocery delivery robot、cartken robot、parts delivery robot、warehouse robots