In the ever-evolving landscape of industrial manufacturing, the integration of artificial intelligence (AI) is catalyzing a profound transformation. From handling a diverse range of materials, optimizing production lines, ensuring timely maintenance interventions to constructing smarter factories, AI is reshaping the manufacturing ecosystem. Harnessing data emanating from factory operations, AI is optimizing workflows, be it at individual production stations or across entire facilities.

Pioneering AI with Pilot Projects

Piloting AI projects serves as an excellent starting point in the integration journey. Experts from industry leaders such as Invisible AI, NVIDIA, and Siemens share compelling success stories that elevate the value proposition for enterprises and propel factories into a new era of intelligence.

AI Revolutionizing Robotic Manipulation

AI has empowered robots to handle novel materials, even unprocessed poultry, by providing them with the ability to recognize and manipulate objects previously deemed challenging. An exemplary collaboration between NVIDIA's client, Soft Robotics, and a food producer showcases an AI solution enabling robots to identify and pick individual moist chicken wings from a pile. The simulation prowess of AI, as highlighted by Gerard Andrews, Senior Product Marketing Manager at NVIDIA, plays a pivotal role. Through synthetic data generation, AI constructs realistic, physically accurate 3D representations, allowing robots to master intricate tasks efficiently.

Figure 1: Soft Robotics worked with a food manufacturer to develop an AI solution that enables robots to recognize And picking individual soggy chicken wings from the pile.

Anomaly Cycle Detection Boosting Production

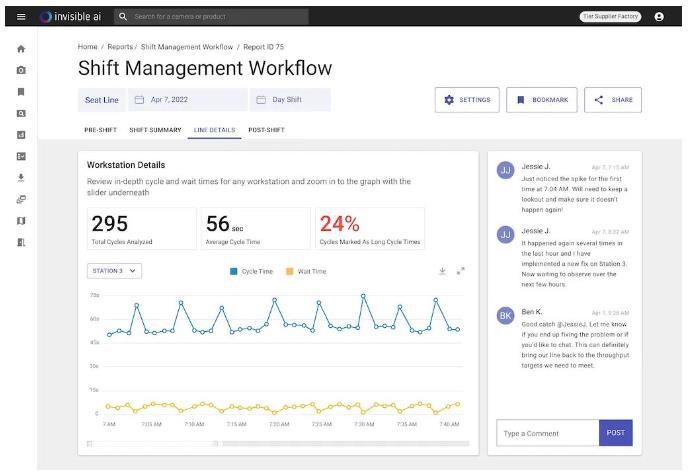

AI serves as a vital tool for management by focusing attention on critical areas. Invisible AI's CEO, Eric Danziger, illustrates how intelligent devices streamline opportunities for optimizing assembly lines. Traditional cameras generate extensive 2D videos, overwhelming in information. However, AI's capability to comprehend images, integrate visual inputs with production data, and craft 3D maps detailing personnel, tools, current productivity, and cycle times revolutionizes management insights. Anomaly cycle detection, a forte of Invisible AI, has proven instrumental in doubling production throughput for a tier-two automotive supplier, revealing high cycle times at specific workstations.

Figure 2: Using artificial intelligence tools, they discovered cycle time spikes at some sites.

Ensuring Timely Maintenance and Quality Control

Drawing parallels with race car drivers and pit stops, timely maintenance and swift interventions are winning strategies. Predictive maintenance, pioneered by AI in industrial environments, predicts machinery failures, allowing maintenance teams to plan replacements before critical breakdowns. Going beyond, prescriptive maintenance adjusts equipment operations to sustain normal functionality. Bernd Raithel, Director of Factory Automation Product Management and Marketing at Siemens, emphasizes the significance of AI in pre-emptive fault identification, reducing downtime and enhancing production efficiency.

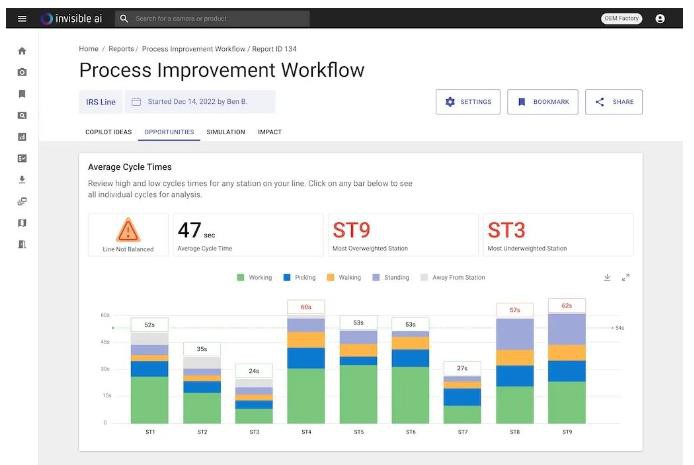

Figure 3: An automotive OEM partnered with Invisible to identify underutilized workstations.

AI-Enhanced Quality Control Through Data Insights

Success in AI applications hinges on the availability of data from production processes. Siemens leverages rich production data to reduce X-ray testing occurrences by 30%, thereby increasing yields in the printed circuit board production line. AI models, informed by extensive data on process results, parameters, and other information, enable the identification of defective parts and their sources, elevating overall product quality.

Simulating New Factories and Processes with Flexibility

Mitigating risks associated with new factory designs and process changes is achievable through 3D simulations in virtual factories, also known as digital twins. These systems, intricately connected to existing setups, provide a lifelike representation of real-world factories. Industry metaverses, such as the collaboration between NVIDIA and Siemens, empower manufacturers to experiment with new designs and processes virtually, ensuring confidence in successful real-world implementations.

From manipulating chicken parts to establishing entire virtual factories, industrial manufacturers are leveraging AI in both the physical and virtual realms. As AI continues to enhance flexibility and optimization opportunities, the prospects for its application in industrial manufacturing are virtually boundless. Reeman Robot stands at the forefront, contributing to this revolution and paving the way for a future where AI seamlessly integrates with every aspect of industrial processes.

Please click on the link below to read more:

Market Analysis Report: SAIL Cleaning Robot

What Have Delivery Robots Done To Improve The Way We Work?

Would you like to know more about robots:https://www.reemanrobot.com/