In the ever-evolving landscape of industrial automation, Reeman Robotics takes a significant leap forward with the introduction of the Reeman RUBY Autonomous Forklift. This cutting-edge forklift is not just a piece of machinery; it represents a transformative approach to material handling, blending advanced technology, precision engineering, and unparalleled efficiency.

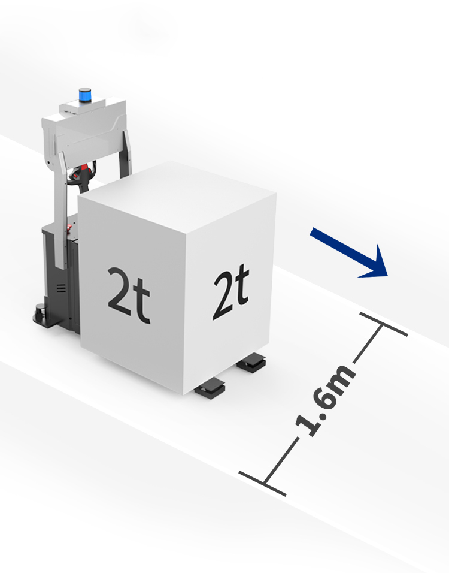

At the core of the Reeman RUBY's capabilities is its impressive 2-ton maximum load capacity. The forklift's sheet metal structure ensures stability and prevents deformation even under heavy loads, allowing it to lift cargo with remarkable ease. With a lifting capacity of up to 12cm, the RUBY proves its prowess in handling diverse materials.

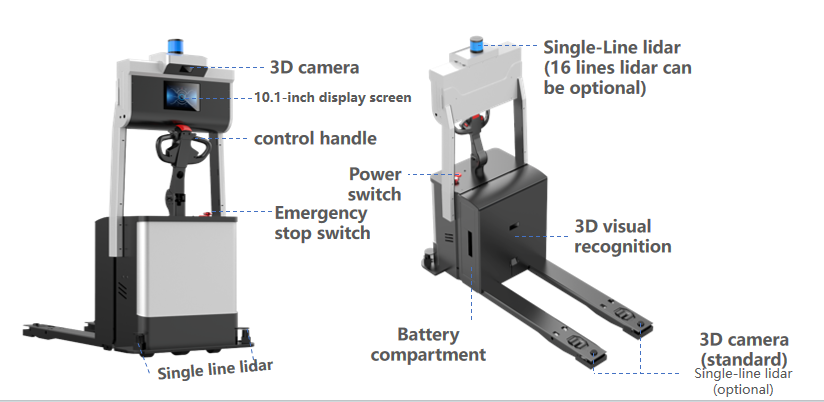

One of the standout features of the Reeman RUBY is its reliance on laser SLAM navigation without the need for reflectors. This innovative approach makes deployment exceptionally convenient, streamlining the setup process for users. The forklift is equipped with a forklift-specific PLC execution system and a dedicated industrial computer, ensuring optimal performance in material transportation tasks.

Navigating through narrow spaces is a common challenge in industrial environments. The RUBY addresses this with its slender body and small swivel radius, making it ideal for applications in narrow channels. The inclusion of 3D obstacle avoidance, safety edge contact, and other sensors provides 360° three-dimensional safety protection, positioning the Reeman RUBY as the best choice for pallet cargo handling and material transportation.

The forklift's intelligence extends to its autonomous obstacle avoidance capabilities, thanks to the integration of a 3D camera and lidar system. This combination allows the RUBY to achieve flexible steering and navigate through a 1.6-meter narrow aisle with ease. The impressive 150-meter detection range caters to the navigation, mapping, and usage needs of expansive factory environments spanning up to 40,000 square meters.

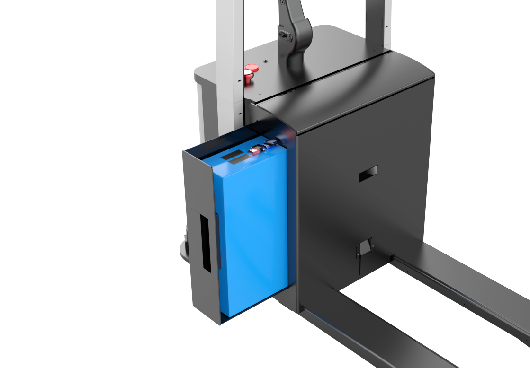

Efficiency is a hallmark of the Reeman RUBY's design. Its robot speed can be dynamically adjusted based on task priority, ensuring both efficient and stable delivery of materials. The detachable battery design enables automatic recharging at low power levels and supports super-fast charging, completing the charging process in just one hour.

Reeman Robotics takes pride in its multi-sensor fusion technology, combining the independently developed SLAM synchronized positioning and mapping system with lidar and 3D camera technology. This holistic approach allows the RUBY to fully perceive its surroundings, operating efficiently and stably in various complex environments.

The versatility of the Reeman RUBY is further emphasized by its ability to drive in both directions, eliminating the need to turn around in confined spaces. The narrow 1.6-meter aisle capability allows the forklift to navigate freely, providing smooth and efficient material handling.

The forklift's user-friendly interface is highlighted by the real laser SLAM technology, eliminating the need for coding. This hand-to-hand integration ensures easy switching between tasks, making the Reeman RUBY an intuitive and adaptable solution for diverse industrial applications.

In a testament to its versatility, the Reeman RUBY finds widespread applications in modern logistics, manufacturing, factory workshops, ports, stations, airports, freight yards, warehouses, circulation centers, and distribution centers. Its multi-machine collaboration capabilities enable orderly operations, preventing bottlenecks in material handling processes.

In conclusion, the Reeman RUBY Autonomous Forklift stands as a beacon of innovation in the realm of material handling. With its advanced features, robust design, and seamless integration into various industrial settings, it is poised to redefine efficiency and safety standards in the world of autonomous forklifts. As industries continue to embrace automation, the Reeman RUBY paves the way for a future where material handling is not just efficient but also intelligent.

Please click on the link below to read more:

Mobile Aloha: A Breakthrough In Humanoid Robotics Unleashes The Era Of Versatile Robots

Revolutionizing Manufacturing With Reeman's Cutting-Edge AMR Technology

The Rise Of Autonomous Mobile Robots: Market Dynamics And Future Outlook

Would you like to know more about robots:https://www.reemanrobot.com/

Autonomous Forklift, Reeman RUBY, Driverless Forklift, Forklift Automation, Industrial Robotics

Material Handling Automation, Laser SLAM Navigation, 3D Obstacle Avoidance, Narrow Aisle Forklift, Multi-Sensor Fusion Technology

Smart Logistics, Warehouse Automation, Robotics in Manufacturing, Efficient Material Transportation, Factory Automation, Autonomous Vehicles, Precision Engineering, Industrial AI, Reeman Robotics, Innovative Forklift Technology