In the era of surging waves of science and technology, the new quality productivity is like a clear stream, injecting new vitality into economic development. It is not only the upgrade of traditional productivity, but also a new engine to lead the future high-quality development. On the road of high-quality development, industrial robots, as representatives of new quality productivity, are leading the transformation and upgrading of manufacturing industry. With the in-depth application of Hongdao Intewell operating system, KDOM Software continues to promote the progress of industrial robotics technology and help enterprises realize a more efficient, smarter and more sustainable production mode.

Hondo Iewell new industrial robot control system solution

I. Background

Control system is one of the core competitiveness of industrial robot manufacturers. At present, some industrial robot controllers rely on foreign chips and their supporting operating systems for system functions and application development, and there is a risk of "necking" in both hardware and software. In the control system, human-computer interaction interface (demonstrator) and motion control were used in different hardware architecture and software program platform, data interaction through the protocol, with the development of business, this hardware and software platforms are independent of their respective architectures in terms of cost, volume, development difficulty, etc. gradually competitive, the architecture of a more unified display and control integration has become a trend.

For the future of data interconnection, the robot control system needs to be more powerful scalability, such as PLC ecology based on IEC61131-3 standard and docking industrial bus, OT/IT protocol support, etc., and therefore also put forward a new generation of robot control system architecture with higher degree of integration and greater scalability requirements.

Aiming at the development trend of localization, high integration and multi-ecological development of industrial robot control system, KDOM Software and Guangdong, Hong Kong and Macao Bay Area (Guangdong) National Innovation Center jointly openEuler open source community to provide a new industrial robot control system solutions.

Solution

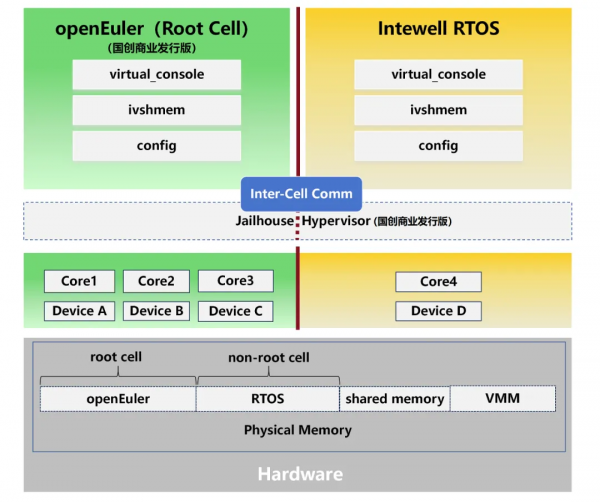

KDOM Software's new industrial robot control system relies on the superior performance of domestic Soc-Rexchip RK3568J, and adopts the underlying virtualization technology to achieve multi-core and multi-OS hybrid deployment, integrating the control state in the hard real-time system, and the interaction state in the soft real-time system. The hardware isolation boundary provided by the virtualization technology ensures that each instance of the real-time system receives sufficient resources and priority, and at the same time, through the real-time clock synchronization and memory sharing mechanism, it can be used for core and memory sharing. The hardware isolation boundary provided by the virtualization technology ensures that each real-time system instance receives sufficient resources and priority, while the high-speed data interaction between cores is carried out through the real-time clock synchronization and memory sharing mechanism.

On the hard real-time system side, Intewell RTOS gives full play to its high real-time characteristics to meet the millisecond control cycle and microsecond jitter performance requirements for robot multi-axis motion control, and is compatible with mainstream industrial ecosystems such as CODESYS, Phoenix MULTIPROG and industrial communication environments such as EtherCAT, Modbus-TCP/RTU, CANOpen, OPC-UA and so on. OPC-UA and other industrial communication protocols.

The soft real-time system side adopts the openEuler-based Guochuang commercial release system, which realizes non-real-time application functions such as robot tutor application, information collection, OT/IT fusion and so on.

The integrated development tool platform can simultaneously develop non-real-time system applications and real-time system applications in a single development environment. The development environment is integrated with Microsoft VS Code environment to provide application development support for RTOS and Linux platforms.

Through the multi-core multi-OS architecture solution, it not only realizes the integration of robot control system display and control, but also expands the industrial ecology and OT/IT integration ecology, and enhances the overall competitiveness of the robot control system in the application of intelligent production line.

System Architecture Diagram

Customer Value

01Cost reduction

High degree of integration, low space occupation, the overall hardware cost can be reduced by about 30%.

02Software Definition

Through the virtualization of hardware resources, elastic allocation of computing resources, improve the flexibility and utilization of the system, reduce the difficulty of system operation and maintenance.

03Stable and Reliable

The microkernel architecture of Hongdao's Intewell operating system provides strong real-time and deterministic time partitioning technology, which effectively improves the performance and stability of robot control.

04Open Ecology

Hongdao Intewell OS supports CODESYS and Phoenix MULTIPROG ecosystem, which improves the compatibility and expandability of the control system in PLC control, motion control and other industrial applications.

05Development Efficiency Improvement

The unified development tool platform reduces the difficulty and investment in development, deployment, debugging and operation and maintenance of the system, and the collaborative efficiency of the application development of each module is improved, which facilitates the rapid iteration and optimization of the system.

From catching up to becoming a pioneer, innovation is the first power to lead development. Hongdao Intewell operating system not only sets a new benchmark for the industrial robot field, but also injects new impetus for the high-quality development of the entire manufacturing industry. By upgrading the level of production automation, improving stability and reliability, optimizing resource allocation, as well as enhancing the flexibility and adaptability of production, Hongdao Intewell operating system is helping enterprises to realize the transformation and upgrading from traditional manufacturing to intelligent manufacturing. Looking to the future, KDO Software will continue to be committed to innovation, help promote the development of new quality productivity, and contribute to the continued prosperity and progress of China's manufacturing industry.